In the ever-evolving landscape of oil and gas operations, efficiency and precision are paramount. Traditional methods of monitoring rod-pump systems relied on manually recording and analysing dyna cards, a critical tool for assessing downhole pump performance. With around 256 points captured per minute, this process was time-consuming and presented significant operational challenges, especially in remote and difficult-to-access oil fields. The need for a more intelligent , faster, and efficient monitoring system was evident.

With the objective of maximising production efficiency, enhancing reservoir management, reducing costs, and ensuring operational safety, Cairn embarked on a journey to enable real-time monitoring and optimisation of SRP, HRP, ESP, and PCP wells. This ambitious vision demanded a bold technological leap forward, one that would shift the approach from reactive to proactive, harnessing the power of advanced digital solutions.

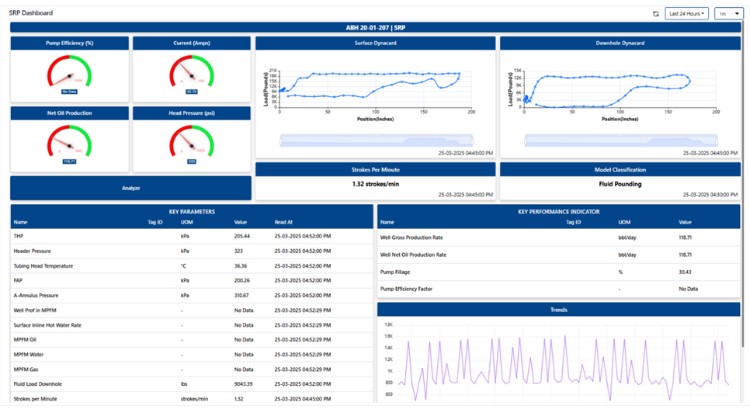

To address these challenges, an innovative solution was introduced, integrating IoT technology, machine learning, and predictive analytics. A network of 37 EDGE IoT Gateway Devices was deployed across 70 wells at the RJ site, enabling seamless real-time data collection and remote monitoring. Machine learning algorithms were employed to analyse and characterise dyna cards, unlocking deeper insights and improving the accuracy of performance assessments. Predictive analytics further strengthened the system’s capability, allowing for early identification of potential failures and reducing well downtime. The Edge Device Management (EDM) Application played a critical role in managing these assets efficiently, ensuring smooth operations and minimising disruptions.

The impact of this initiative has been transformative. Real-time data acquisition has provided operators with instant access to crucial well performance parameters, eliminating delays associated with manual data collection. Machine learning-driven intelligence has enhanced decision-making, enabling timely interventions that optimise pump efficiency and field performance. By shifting from a reactive to a proactive approach, well interventions and production losses have been significantly reduced. The ability to anticipate failures and minimise unplanned downtime has directly contributed to improved production stability, ensuring that operations continue without unnecessary interruptions.

Successfully implemented across the ABH fields and NE-NI fields of RJ North, this cutting-edge approach is setting a new benchmark in oil field management. By embracing real-time intelligence and predictive capabilities, Cairn is not just improving well monitoring, it is redefining the future of oil and gas operations, demonstrating how innovation can drive efficiency, sustainability, and long-term success.

Contributed by Anoushka Ailawadi